PRO-E will create the features upon specifying the attributes by designer.

PRO-E will create the features upon specifying the attributes by designer.

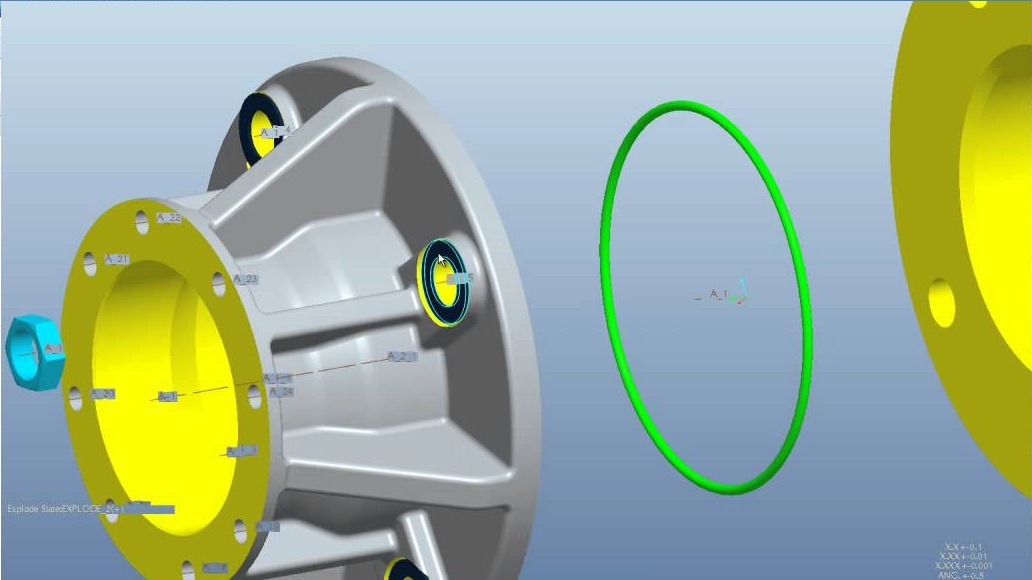

ProE was developed by parametric Technology Corporation, Waltham, MA. ProE is a multi-programs software that can be used for design, analysis and manufacturing. In this portion of the course we will be dealing with the first capability of ProE which deals with the model creation and assembly of designs. However, ProE is linked to another package, MEHANICA, which is able to perform structural, thermal and motion analysis. The structural analysis includes static stress, deformation, buckling and vibration. ProE and MECHANICA can be used for optimization and parametric studies. Connecting ProE to NC machines provide the manufacturing capabilities. Wide range of sheet metal forming, piping layout and model designs can be handled.

In the design and assembly, which is the tool that we are aiming to learn, ProE is considered a powerful tool. The significance of ProE over other existing drafting tools come from its capability of being parametric, feature based solid modeling software. The parametric capability of ProE enable the designers to change certain parameters and dimensions in the feature they are designing and the program will adapt the change through the whole model. For example in design optimization, often designers need to change a particular dimension of a particular feature to fit with the rest of the model. ProE enable the designer to change the dimension and ProE will propagate the change to the rest of the model.

ProE is a feature based software were parts are created by defining features such as extrusion, sweep, cuts, holes, slots, rounds and so on. ProE will create the features upon specifying the attributes by the designer. The solid model that is created by the ProE should be feasible. ProE will not perform a task that may not lead to a solid model. It should be emphasized here that not all solid models are manufacturable models.Androbim is the Best Pro-E training institute in Hyderabad.